|

Reel hub crack.

It is very probable that this one is cracked. Sometimes it can result in the plastic reel coming off. The fix is very simple, glue it to the axle.

Take-up assembly black part crack

Procedure is very similar to fixing the small source reel gear. Split it from the reel axle and increase the hole size using the 2.0 mm mill bit. If it is already cracked, then glue it to the axle. If it is cracked too much, then it can interfere with the small white gear moving up and down. In this case, you should carefully shape it using filing and sanding.

Plastic slider crack

This is one of the most complex parts and if something happens to it a fix is very difficult. But heads-up, it is possible. Unfortunately the probability that this part is broken is very high. From my experience one of five sliders have a bigger or smaller problem.

Warning: we should do preventive tasks as soon as possible. There is a time bomb hidden. Sooner or later, all sliders will be cracked, if not treated properly!

Actually, there are two problems that can happen. Fortunately, even if they do happen, both can be fixed.

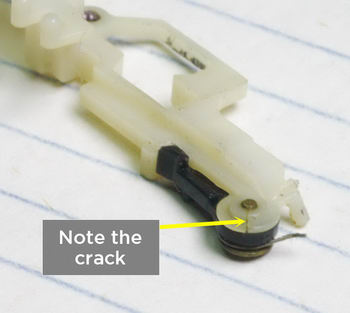

Problem 1: Crack around the metal pin

Preventive task: Remove the metal pin and reduce its size a little (best using sand paper).

How to fix it: It’s not big problem and a fix is quite easy. Glue the metal pin to its hole. Do not try to glue the crack itself. It will have no effect. Remember, the black plastic part needs to stay movable. Apply only a very small amount, using the tip of needle, for example.

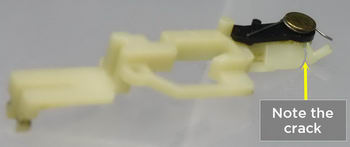

Problem 2: Crack or deformation of round jut

This is a very common problem. The spring pushes permanently on the top of the plastic jut, and this permanent load results in plastic deformation and crack. Sooner or later, each slider will suffer from this problem, if not treated.

Preventive task: It is very simple. We need to ensure that the spring will not be in contact with the plastic slider on the top of the jut, but on its bottom. For this we have to bend the spring wire down a little.

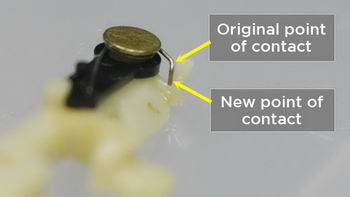

How to fix it? Is it possible to fix such an ugly crack? Sure, yes :) Here is how I do it. I create a new jut from 0.7 mm brass wire. For that I need to drill a 0.7mm hole in the slider, as close to the place where it was cracked as possible. The result can be seen on the following image. Also, it is necessary to bend the spring little.

Fixing broken hinge

It is possible to make a new hinge from a small metal sheet. You will need a high-speed pen engraver and the right tools.

This is how it looks.

You need to glue it to the case. Use a special glue for metal. And don’t forget to roughen the surface to be glued first.

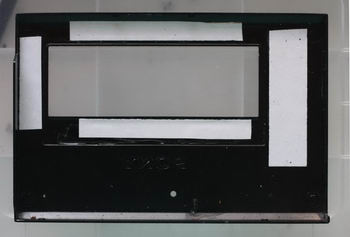

Fixing loosened window

This is a very easy fix. Clean off all remains of old glue. Clean it off very carefully from both the transparent window and the door itself. I do not have good experiences with using glue to bond these two parts, glue doesn’t bond well to plastic. There is also a risk that the glue will protrude and be visible.

I use double-sided duct tape. It is very strong and I have very good experiences with it.

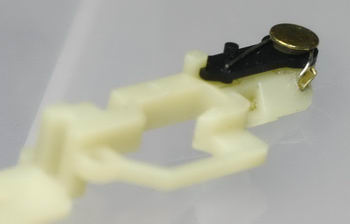

Fixing broken door lock

The image is taken from a walkman I fixed about 5 years ago.

I use it daily, therefore I think the fix is successful. I replaced the broken plastic with brass wire. I drilled two 0.8 mm holes in the slider, formed the 0.8mm wire to a U-shape and inserted (glued) it to the holes. After years of use the result looks a little worn, but still usable.

Fixing two small metal sheets

If it is loosened and doesn’t sit tightly in it’s place, you have to remove it, bend it a little and put it back in.

And... that's it! I hope you enjoyed the guide and it has been of great help. Any comments? Leave them in our forums.

Thanks to Vincenzo (aka Vince666 at Tapeheads.net) for the text correction.

© Copyright text and photos Marian Mihok

|

![]()

![]()

![]()